Durable water repellent

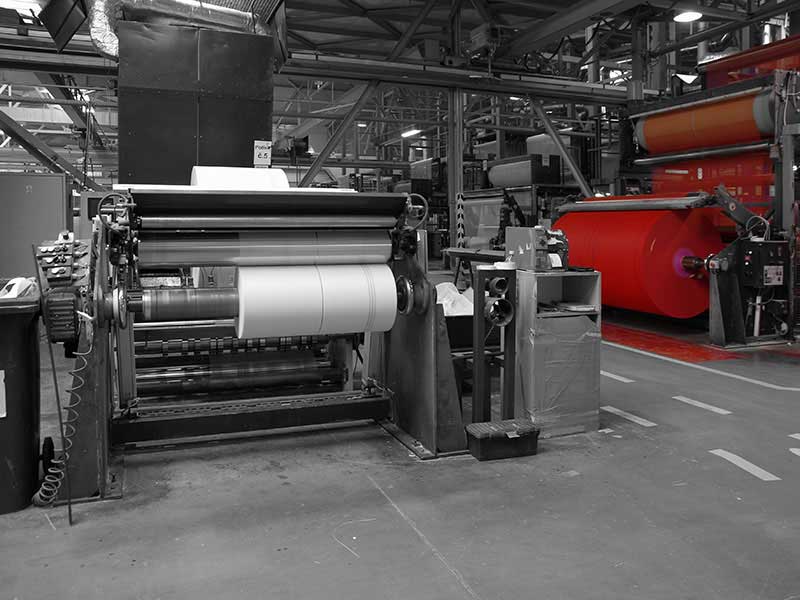

Sustainable, industrial textile finishing (durable water repellents) without C8 or PTFE

Nanotechnology supports the development of fluorine-free (PFC-free) and permanent oil-repellent systems. Even now, it is possible to achieve performance in the dip/foulard process (padding) that is similar to C8 fluorocarbon finishes, but with shorter (C6-C4) and thus less environmentally concerning chains. Greenpeace has been promoting a fluorine-free (PFC-free) textile industry since 2012, which is characterized by ZHDC, MRSL restrictions. Nanotechnology opens-up new possibilities for sustainable textile finishing under the Ökotex 100 standard, which minimizes the use of chemicals and makes them cost-effective. The current ISO and AATCC standards (ISO 14419/ AATCC 118 hydrocarbon resistance test, ISO 4492 / AATCC 22 spray test, ISO 6530 fluid chemicals (Bundesmann Test) are covered. These systems are applied to natural fibres (hemp, jute, sisal, cotton, wool, cashmere, angora), leather, cellulosic man-made fibres (viscose, modal or acetate), synthetic man-made fibres (polyester, polyamide, elastane, nylon or polyacrylic). Applications include nano-coatings for water repellency on membranes, laminates, functional textiles (rainwear, winter clothing, outdoor textiles, tarpaulins, umbrellas, awnings, convertible car-tops), bulletproof clothing, military uniforms, textiles in the automotive sector, the health sector (emergency rescue clothing), traditional costumes, workwear, but also sportswear (track suits, shoe soles, sweatbands) for odour control through permanently hygienic equipment.